Quick post to explain how to upload the original Arduino nano 33 BLE bootloader in case you erased it by mistake (another story for another post)…

Hardware

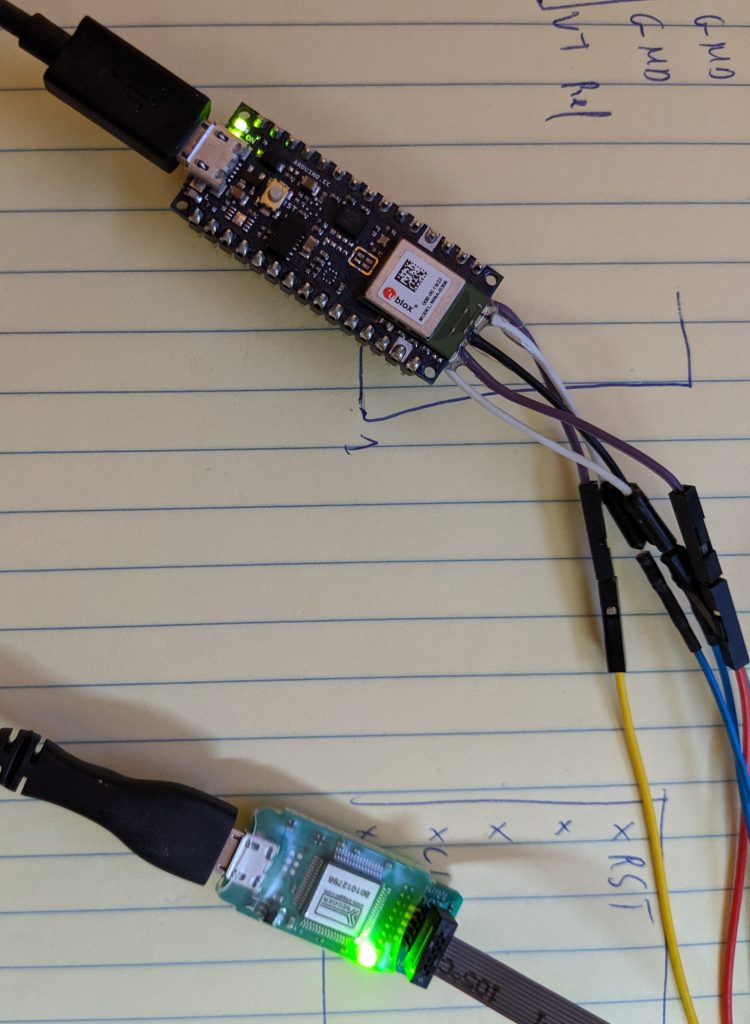

I have a J-Link EDU Mini as external programmer for the chip of the board (Nrf52840 – https://www.nordicsemi.com/Products/Low-power-short-range-wireless/nRF52840) It s a very cheap programmer (15$) that can only be used for non commercial application but offer the same functionality that a 400$ programmer. Thx Nordic for offering that to hobbyist ! More info about it here: https://www.segger.com/products/debug-probes/j-link/models/j-link-edu-mini/

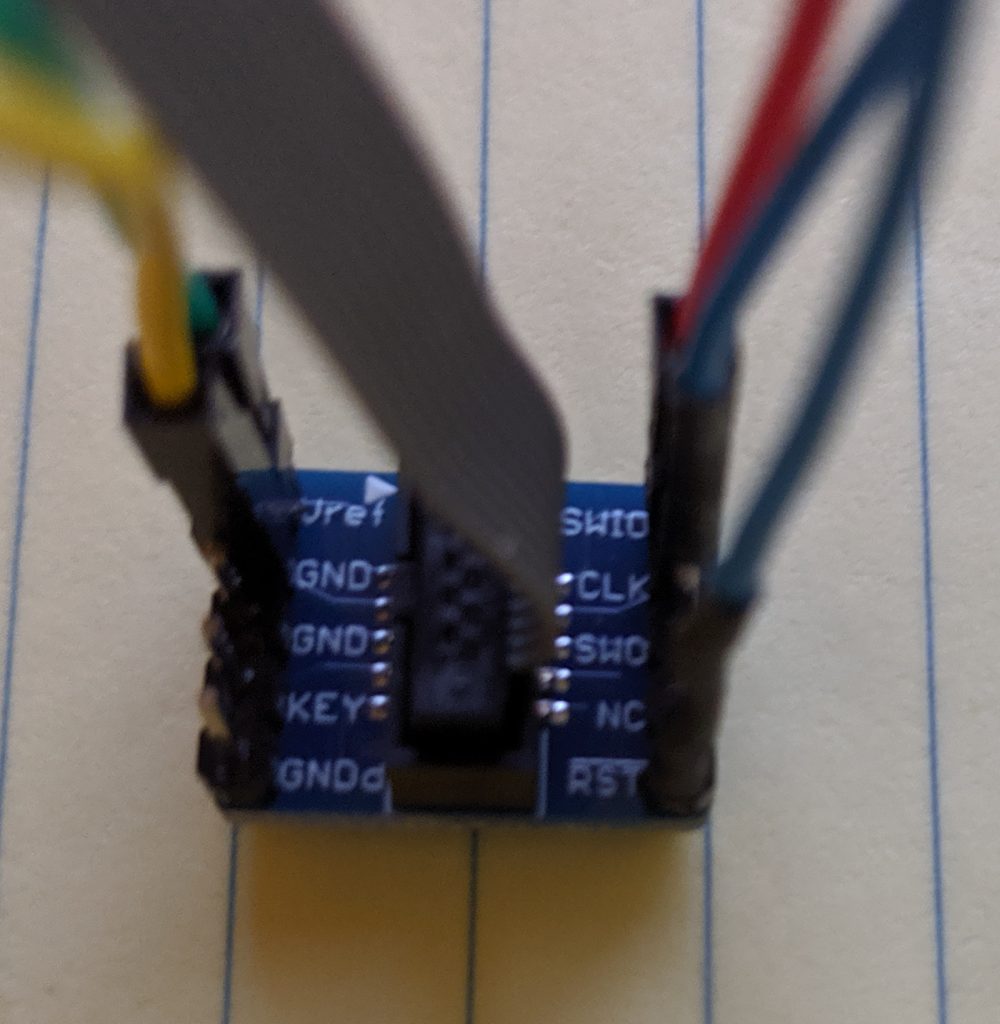

I would also suggest to buy an adapter for it “designed to make it easier to use ARM dev boards that use slimmer 2×5 (0.05″/1.27mm pitch) SWD cables for programming” like this one: https://www.adafruit.com/product/2743

Connection

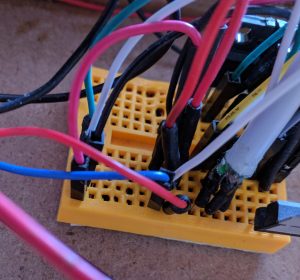

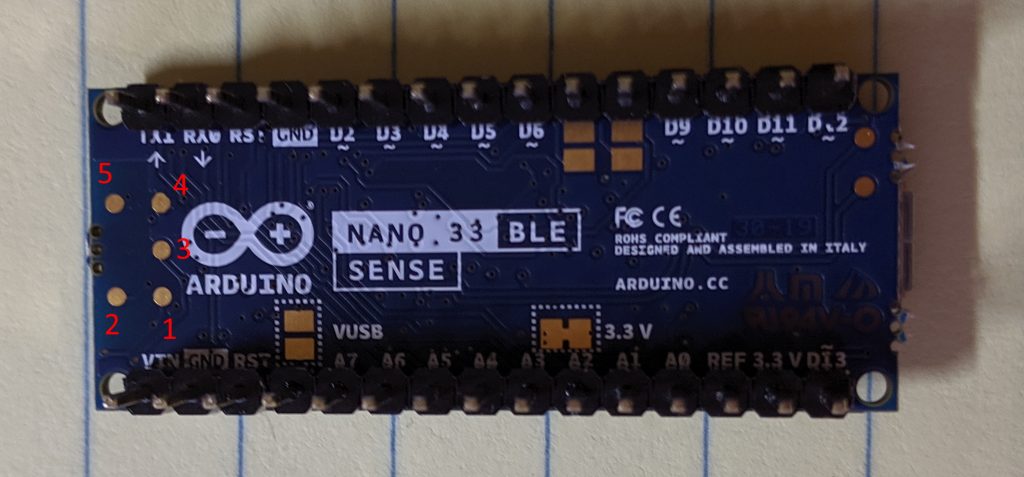

There are 5 cables to connect between the Arduino nano 33 BLE and the J-Link programmer but first let’s locate the Probe on the Nano 33 BLE (I used another nano 33 BLE sense board in pic but it is the same as the Nano 33 BLE).

The pins are:

1 – Vref (3.3V in our case)

2 – SWDIO (data)

3 – SWCLK (clock)

4 – Ground

5 – Reset

The tricky part will be to solder the cable because all the points are small and close to each other (I wish they expose them with a more practical way but we are lucky to have access to them already;) )

The mapping of the J-Link is explain on the official doc https://www.segger.com/products/debug-probes/j-link/models/j-link-edu-mini/ and it s even better if you use the adapter since the name will be written of it

The mapping is thus

| Nano 33 BLE | J-Link EDU |

| Vref | Vref |

| SWDIO | SWIO |

| SWCLK | CLK |

| Ground | GND (any) |

| Reset | RST |

Software

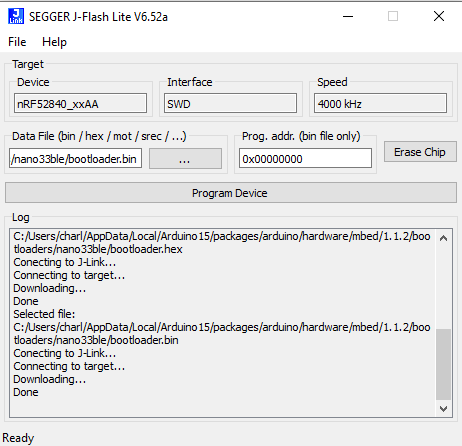

You need to full J-link package (which is free) that you can download on Nordic website here: https://www.segger.com/downloads/jlink/ We are going to use J-Flash lite to be specific but better install the whole package 😉

Turn on the 2 board (don t forget to plug tha nano 33 or Vref will be 0V and J-Link will fails to connect to the Arduino board).

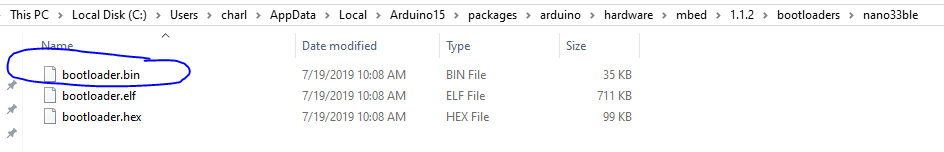

We need to locate the Arduino Bootloader of the nano 33 BLE file that we are going to upload with J-Flash lite….. It is located here C:\Users\charl\AppData\Local\Arduino15\packages\arduino\hardware\mbed\1.1.2\bootloaders\nano33ble (of course you need to adapt) and contains 3 files

We are going to use the bin one (should works with hex one too) and give this path in J-Flasher. Be sure to choose nrf52840 in the list of device (the rest of parameters can stay with their default value) and then click “Program Device”.

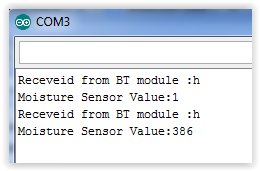

You should had some logs similar to these one and then the board should have back its original Arduino bootloader and should be usable again in the Arduino UI 😉